|

Technical Note

INFLUENCE OF COMPACTION

TEMPERATURE

ON SEAM MIX AIR VOID CONTENT

Background

It has been observed in the field that

“rigid” 50%SEAM/50%Bitumen wt. binder mixes exhibit higher air void

contents after compaction than lower SEAM/Bitumen weight ratio mixes.

While studies by the U.S. Bureau of Mines* have

indicated that such “rigid”, high air void content mixes still exhibit

higher Marshall stabilities, even when densified at temperatures as low

as 85 °C, than highly compacted conventional asphalt

mixes, low mix air voids are generally favored by most agencies to

minimize mix access to air, in order to reduce bitumen oxidation, and to

reduce water intrusion in mix, in order to minimize moisture damage

potential. Actual field performance of higher void SEAM mixes has been

shown to be good. <Ref: SEA pavement evaluation [FHWA-Liddle &U 0f W-

Mahoney] Sulphur-84 International Conf. 1984>

Laboratory Mix Compaction Studies

Laboratory

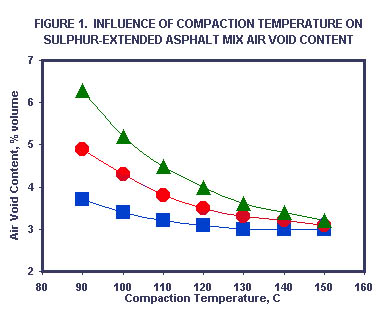

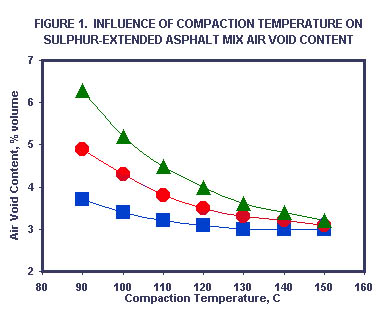

Marshall compaction studies in Figure 1 confirm that while mix air void

content increases when mixes are compacted at a lower temperature, this

increase is not significant for the “flexible” 30%Sulphur/70%Bitumen mix

but starts to become significant at lower temperatures for the

“semi-rigid” 40%Sulphur/60%Bitumen mix and is very significant for the

“rigid” 50%Sulphur/50%Bitumen mix.

|

<

30%Sulphur/70% Bitumen

l

40%Sulphur/60% Bitumen

p

50%Sulphur/50% Bitumen |

* Reference: US Department

of Transportation FHWA-IP-80-14

|

Recommendations

In order to reduce

mix air void content, it is recommended that SEAM mixes be compacted at

acceptably high temperature levels. The options for doing this are the

following:

1.)

“Tightening up” breakdown and

intermediate rolling to compact mixes immediately after placement.

2.)

Use of a mass transfer

vehicle (with a re-mixer) to improve mix temperature uniformity, and

thereby improve mix compaction potential.

3.)

Design “semi-rigid” and

“rigid” mixes to a lower air void content, e.g. 2% target, anticipating

the higher air void content in the field. This may require slight

changes in aggregate gradation.

|

![]()