![]()

Home

SEAM

ARP

Laboratory

Procedure

Safety

About Us

History

Contact Us

Integrated Sampling Technologies 5401 Rusty Anchor Ct. 12/5/01 W.R. Bill Bailey Dear: Bill This letter confirms my visit to Frehner Construction's asphalt paving job on the northern portion of the I-215 beltway in Las Vegas, NV on November 6, 2001 and the Wells Cargo asphalt paving job at Rainbow and Hacienda in Las Vegas, NV on November 7, 2001. The purpose of this visit was to assist you in evaluating exposure to Sulfur Dioxide air contaminants generated as a result of the sulfur-asphalt product versus a typical polymer-asphalt product. Attached is the report that contains an Executive summary, Discussion, Recommendation, Sampling methodologies, Results and Health hazard data section. Our survey should not be considered exhaustive or inclusive of all potential hazards that could have existed during the survey. I would like to thank you and the employees involved for the assistance and cooperation that they extended on the day of my visit. I am looking forward to working with you in the future. If you have any questions regarding this report or the attached materials please feel free to call. Sincerely,

Terry D. Evans, OHST

cc:

This correspondence is advisory only. It does not attempt to list all existing hazards, or to indicate that if other hazards exist, they are adequately controlled. Safety of your premises, products, operations, employees and other persons are your primary responsibility and this opinion does not relieve you of this responsibility. EXECUTIVE SUMMARY:Employee exposures to the air contaminant, sulfur dioxide, measured on the days of our survey were not in excess of the current OSHA 8hr TWA PEL. Employee exposures were also below those recommended in the 2001 American Conference of Governmental Industrial Hygienist (ACGIH) 8 hour TWA Threshold Limit Values (TLVs). DISCUSSION:Sampling on the Rockbinders sulfur-asphalt products being used by Frehner Construction was conducted in good weather conditions at the northern section of I-215 with light to moderate winds and no rain. The asphalt was laid in windrows along a new roadbed. There was no fume capture equipment installed on the asphalt-laying machine. There was a portable generator for lights running on the paver. Sampling of the comparison, a typical polymer-asphalt product being used by Wells Cargo, was conducted in good weather conditions at the intersection of Rainbow and Hacienda with light winds and no rain. The asphalt was laid directly into the hopper of the asphalt machine and laid onto an existing roadbed. There was no fume capture equipment installed on the asphalt-laying machine. Both air-sampling studies were conducted using the same type of sampling equipment and media configured in the same manner for each study. Both sets of samples were analyzed by the same laboratory using the OSHA ID-200 method. Results obtained apply to conditions observed at the time of the survey. Changes in production, materials in use, employee work methods, weather conditions, seasons, and other factors may cause employee exposure to vary. Also, not every possible chemical contaminant or physical agent was evaluated. RECOMMENDATIONS:IH-01-1 Repeat the monitoring for this contaminate if there is any significant change in the formulation of the asphalt mix. IH-01-2 The employees that participated in the exposure monitoring should be given a copy of the sample results. IH-01-3 You should keep this report on file for documentation purposes. Our recommendations are based upon good Industrial Hygiene principles, practices and regulatory standards. Exposure assessments include a review of other standards besides the Occupational Safety and Health Administration (OSHA), Permissible Exposure Limits (PEL s). These additional standards include the National Institute for Occupational Safety and Health (NIOSH), Recommended Exposure Limits (REL s), and the American Conference of Governmental Industrial Hygienists (ACGIH), Threshold Limit Values (TLV s). These are generally based on more current toxicological and epidemiological data. Therefore, our opinions and recommendations are based on the most recent available information and not solely on regulatory compliance. Additional information regarding these standards is included in the Appendix following the Data Section of this report. This report should not be considered exhaustive or inclusive of all potential hazards that could have existed during the survey. Please let me know if you have any questions on these or other Industrial Hygiene concerns.

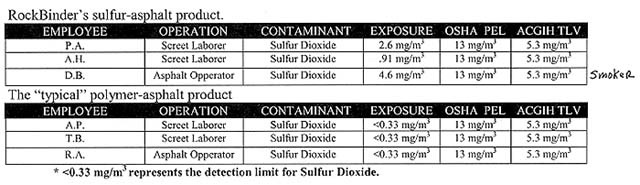

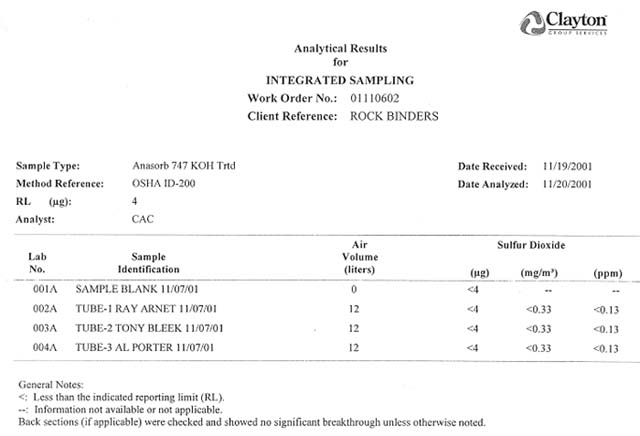

SAMPLING METHODOLOGIES:The laboratory that conducted the analysis is accredited by the American Industrial Hygiene Association (AIHA) and participates in the proficiency in analytical testing (PAT) program administered by the National Institute of Occupational Safety & Health (NIOSH) and the AIHA. Sampling instruments were calibrated to a primary standard, before and after sampling was completed. Additional analytical and sampling details are available upon request. It should be noted that the sampling data presented in this letter represent point-in-time samples and should not be considered to apply under all conditions. Factors such as individual employee procedures, varying production levels, changes in the operation or materials and many other factors, individually, or in combination, may alter employee exposure parameters, and, therefore, sampling data. An effort was made, however, to conduct the sampling as much as practical under representative conditions. RESULTS:Listed below are the results of the air sampling the results have been extrapolated to reflect the employee's 8-hour exposure dose. Exposure levels found on the day of the survey have been compared with the current OSHA 8-hour TWA PELs and ACGIH 8-hour TLVs. The OSHA PELs are workplace standards, are enforceable by law, and for the most part are 1971 TLVs. ACGIH TLVs are advisory standards and are changed as health hazard data, epidemiological studies and workplace observations warrant. Both the OSHA PELs and the ACGIH TLVs are designed to protect most workers for an 8-hour day, 40-hour workweek for a working lifetime. However, they may not protect highly susceptible employees or employees with pre-existing medical conditions. Neither should be interpreted as a line between safe and unsafe exposure. Employee exposure to all toxic substances should be kept as low as feasible in an attempt to protect the health of your workforce.

HEALTH HAZARD DATA:Attached is the health hazard data that outlines the acute and chronic health hazards of the contaminants measured on the day of the visit. SULFUR DIOXIDE:Sulfur dioxide is also known as bisulfite, SO2, sulfurous acid anhydride, sulfurous anhydride, sulfurous oxide, soulfur oxide, sulphur dioxide, and dioxide de soufre. Sulfur dioxide (SO2) is a moderate to strong irritant, extremely irritating to the eyes and respiratory tract. most inhaled SO2 only penetrates as far a the nose and throat with minimal amounts reaching the lungs unless the person is breathing heavily, breathing only through the mouth or the concentration of SO2 is high. Sensitivity varies among people, however, short exposure (1-6 hours) to concentrations as low as 1 ppm may produce a reversible decrease in lung function. A 10 to 30 minute exposure to concentrations as low as 5 ppm has produced constriction of the bronchiole tubes. Only one of eleven volunteers showed any effects at 1 ppm. A 20-minute exposure to 8 ppm has produced reddening of the throat and mild nose and throat irritation. About 20 ppm is objectionably irritating, although people have been reported to work in concentrations exceeding 20 ppm. 500 ppm is so objectionable that a person cannot inhale a single deep breath. In severe cases where very high concentrations of SO2 have been produced in closed spaces, SO2 has caused severe airways obstruction, hypoxemia (insufficient oxygenation of the blood), pulmonary edema (a life threatening accumulation of fluid in the lungs), and death in minutes. The effects of pulmonary edema include coughing and shortness of breath which can be delayed until hours or days after the exposure. These symptoms are aggravated by physical exertion. As a result of sever exposures, permanent lung injury may occur. Sulfur Dioxide is heavier than air. It reacts violently with ammonia, acetylene, chlorine, ethylene oxide, amines, butadiene and others. Reacts with steam and water. Attacks metals. Its major use is a captive intermediate in the production of sulfuric acid. In the pulp and paper industry, sulfur dioxide is used to produce other chemicals such as chlorine dioxide and sodium hyposulfite and is also used in the bleaching of pulp. In food processing, sulfur dioxide is used for fumigating, preserving, bleaching and steeping. it is also used to reduce residual chlorine in potable water, treated sewage and industrial effluent, as an oxygen scavenger, a selective extraction solvent and as a catalyst in chemical processes. In the presence of a catalyst (e.g. nitrogen compounds), sulfur dioxide can be oxidized to sulfuric acid. Occurs as a by-product during the burning (combustion) of sulfur containing organic compounds (e.g. coal). A common component of air pollution, it is a major contributor to acid rain.

|