![]()

REQUIREMENTS FOR INJECTING

SEAM or ARP

INTO THE ASPHALT HOT PLANT

Home

SEAM

ARP

Laboratory

Procedure

Safety

About Us

History

Contact Us

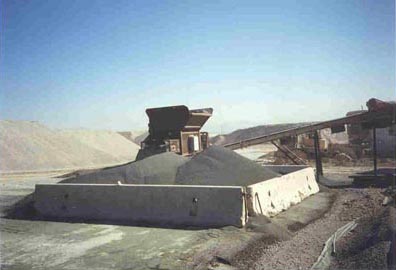

DRUM PLANTS

The solid binder material shall be accurately metered into the mixing portion of the

drum within one foot of the asphalt oil injection point or into the after-mixer with an

approved proportioning apparatus suitable of ICC certification for custody transfer of

materials. (i.e.; belt scale, metering auger, or similar).

The solid binder material shall be accurately metered into the mixing portion of the

drum within one foot of the asphalt oil injection point or into the after-mixer with an

approved proportioning apparatus suitable of ICC certification for custody transfer of

materials. (i.e.; belt scale, metering auger, or similar).

The solid binder shall be added to heated aggregate which shall provide a minimum mix temperature of 265 ° Fahrenheit. The maximum mix temperature shall not exceed 290 ° Fahrenheit at the discharge point of the drum. Mix above or below these temperatures shall be rejected.

* The above mentioned addition point shall also include RAP collars if they are "newer generation" collars which do not have direct flame contact with the RAP and/or solid binder. (i.e.; CMI or Astec double drum or similar). This method shall utilize the above mentioned metering devices and at no time will the solid binder be directly exposed to open flame. An appropriate H2S audible detector shall be installed within two feet of the discharge of all plants being used and be capable of registering a min. of 10 ppm. At no time shall the reading exceed the amount required in accordance with O.S.H.A. standards.

BATCH PLANTS

The solid binder material shall be accurately metered into the mixing portion of the

pug mill during the period of the batching process where the addition of the asphalt oil

normally occurs. This can be accomplished on a weight basis by a certified scale or with

an approved volumetric device that has an approved proportioning apparatus suitable of ICC

certification for custody transfer of materials. The minimum mix time shall be 20

seconds with 30 seconds preferred. The solid binder shall be added to heated aggregate

which shall provide a minimum mix temperature of 265 ° Fahrenheit. The maximum mix

temperature shall not exceed 290 ° Fahrenheit at the discharge point of the plant. An

appropriate H2S audible detector (such as a Dreager or other) shall be installed within

two feet above the discharge of the plant and be capable of registering a min. of 0.5 ppm.

At no time shall the reading from this unit exceed 50 ppm

or the amount required in accordance with O.S.H.A. standards.

The solid binder material shall be accurately metered into the mixing portion of the

pug mill during the period of the batching process where the addition of the asphalt oil

normally occurs. This can be accomplished on a weight basis by a certified scale or with

an approved volumetric device that has an approved proportioning apparatus suitable of ICC

certification for custody transfer of materials. The minimum mix time shall be 20

seconds with 30 seconds preferred. The solid binder shall be added to heated aggregate

which shall provide a minimum mix temperature of 265 ° Fahrenheit. The maximum mix

temperature shall not exceed 290 ° Fahrenheit at the discharge point of the plant. An

appropriate H2S audible detector (such as a Dreager or other) shall be installed within

two feet above the discharge of the plant and be capable of registering a min. of 0.5 ppm.

At no time shall the reading from this unit exceed 50 ppm

or the amount required in accordance with O.S.H.A. standards.

* IMPORTANT NOTE;

AT NO TIME SHOULD THE SEAM OR ARP COME IN DIRECT CONTACT WITH THE FLAME OR HEAT PLUME. TREAT THESE PRODUCTS AS YOU WOULD ASPHALT OIL (BITUMEN) IN THE PROCESS. THEY SHOULD BE ADDED IN THE MIXING AREA OF THE DRUM OR PUG MILL IN THE HOT PLANT.